Let loose Performance in Your Stockroom Workflow With a Top Notch Stretch Wrapping Device

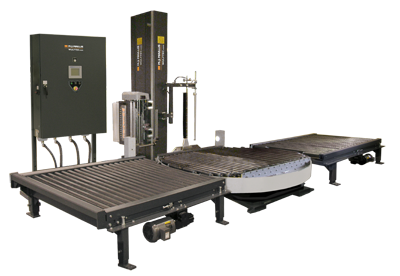

The intro of a premium stretch wrapping maker can be a game-changer, promising effectiveness, reduced labor expenses, and reduced human mistake. With the capability to manage various tons dimensions and wrap numerous pallets per hour, these equipments use a compelling proposition for any business looking to maximize its operations.

Understanding the Role of Stretch Covering Machines in Warehouse Workflow

In the substantial realm of warehouse procedures, the significance of stretch wrapping equipments can not be overemphasized. They offer an essential role in making certain that goods are securely and securely bundled for storage space or transport. These makers use a highly elastic plastic movie around items, securely covering them together in such a way that hand-operated wrapping just can not match.

Stretch wrapping makers can take care of big volumes of goods rapidly, substantially speeding up the packaging process. The uniform wrapping provided by these devices can decrease the risk of tampering or theft during transportation.

Secret Features of High-Quality Stretch Covering Machines

While there is a large range of stretch wrapping equipments available out there, premium versions share specific key attributes that set them apart. These equipments are generally durable, designed to stand up to substantial usage without endangering on performance. They use a high degree of automation, enabling reliable and problem-free wrapping of items.

High-quality stretch wrapping equipments also feature flexible settings, supplying adaptability to fit different packaging requirements. They can manage various dimensions and kinds of tons, making certain a safe cover each time. These makers are additionally renowned for their rate, qualified of wrapping numerous pallets per hour, thus considerably improving performance.

An additional trick attribute is their integrity and reduced upkeep demand. Top notch equipments are constructed to last, minimizing the regularity of malfunctions and the connected downtime. They run with accuracy, making certain consistent cover tension, thus decreasing waste and enhancing the presentation of wrapped products.

The Impact of Stretch Covering Machines on Storage Facility Efficiency

The effectiveness of a storehouse can be substantially improved with the use of high-grade stretch covering devices - stretch wrapping machine. These machines simplify the product packaging process, reducing the manual work included and subsequently, the chance for human error. This makes certain a much more reputable and constant covering process, bring about enhanced safety and security of products during transportation

Furthermore, stretch covering equipments can take care of a higher quantity of items in a much shorter quantity of time compared to hand-operated wrapping. This heightened efficiency can cause much better application of stockroom space as products can be packaged and relocated quicker. The machines likewise supply the flexibility to accommodate different shapes and sizes of items, even more boosting functional effectiveness.

Calculating the Return on Financial Investment for a Stretch Covering Machine

Taking into consideration the significant advantages of stretch covering machines, it's important to understand the economic ramifications of investing in such devices. The roi (ROI) estimation is a simple yet reliable tool to analyze the success this hyperlink of this financial investment. The ROI is determined by contrasting the cost of the equipment with the cost savings generated over a particular duration.

The higher the ROI, the more successful the investment. Nonetheless, this number needs to not be the sole determinant in the decision-making procedure. Organizations need to additionally take into consideration variables such as critical positioning, operational performance, and scalability. Finally, calculating the ROI offers a clear monetary point of view to guide the financial investment choice in stretch covering machines.

Real-world Study: Success Stories of Executing Stretch Covering Machines

Drawing from the financial effects talked about in the previous section, it is equally enlightening to analyze useful applications and success stories of firms that have actually applied stretch covering makers in their operations. One such example is a multinational electronic devices business which reported a 30% decrease in damaged items during transportation after presenting stretch covering devices in their product packaging procedure.

One more success story includes a leading food and beverage firm. After carrying out a stretch wrapping machine, they saw a considerable enhancement in their packaging rate, which subsequently enhanced daily results and general performance.

Finally, a popular furnishings producer had the ability to cut down their you can try here packaging product prices by a shocking 40% after changing to extend covering makers; they simultaneously decreased their carbon impact, making their procedures a lot more sustainable. These real-world case research studies show the impressive returns and effectiveness gains that extend covering machines can give warehouse procedures.

Verdict

To conclude, purchasing a top quality stretch wrapping maker can substantially boost warehouse operations. With its capacity to lower manual work, decrease mistakes, and boost room utilization, it considerably enhances productivity and earnings. The ROI, coupled with success stories from real-world implementations, further underscores the crucial role of stretch wrapping machines in achieving operational efficiency and service success.

The introduction of a top quality stretch wrapping machine can be a game-changer, promising efficiency, reduced labor expenses, and reduced human error.In the vast realm of warehouse procedures, the relevance of stretch wrapping machines can not be overemphasized.The performance of a storehouse can be considerably improved with the usage of top notch stretch wrapping see post machines.In addition, stretch covering devices can handle a greater volume of items in a shorter quantity of time contrasted to manual covering.In final thought, investing in a high-grade stretch covering machine can dramatically improve warehouse procedures.